Steel Fabrication

We recently completed a steel fabrication project that required the welding and project management expertise of the team here at Better Engineering.

We recently completed a steel fabrication project that required the welding and project management expertise of the team here at Better Engineering.

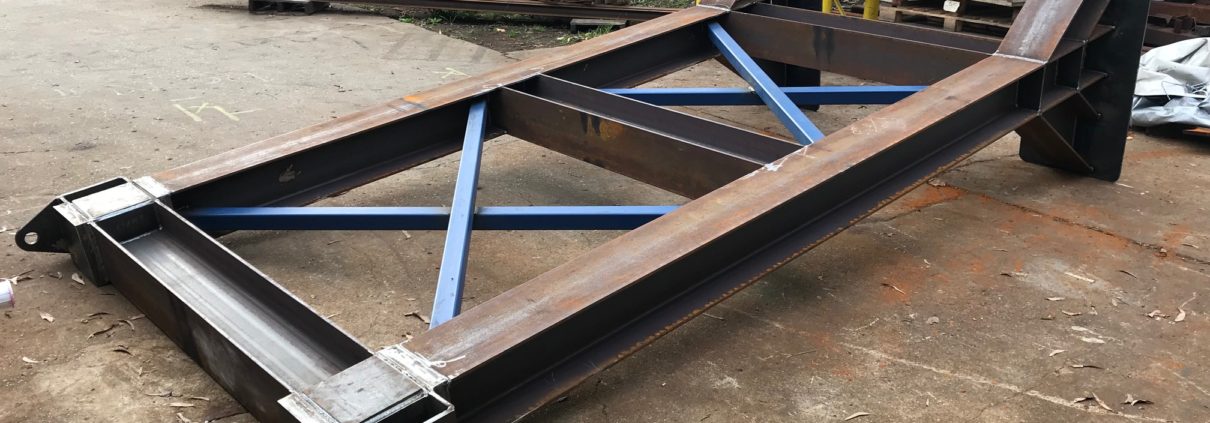

We manufactured a frame to support a crane boom.

The attached photo was taken prior to sandblasting and painting.

When it comes to complex or large steel fabrication projects, talk to Better Engineering. We work on projects for infrastructure companies, Telecommunications companies and large manufacturers.

WHO IS BETTER ENGINEERING?

Better Engineering has been servicing the South-East Queensland market under the same ownership for over 25 years.

It specialised in steel fabrication and welding, taking projects right through from drawings and design, to installation on site. Work is carried out in their Geebung factory and/or on-site, depending on the requirements of the project.

The benefits of having Better Engineering on board include

– Director or senior technician involvement at every step.

– massive bank of industry experience to call on

– acute awareness of project deadlines and budgets.

Get in contact with the team today !

We weld using the following methods

- MIG – used in the workshop as the most cost effective fabrication method for mild steel, stainless steel and aluminium components.

- TIG – used with lighter gauge stainless steel and aluminium fabrications but can also be needed for welding aluminium castings, etc.

- Electrode – used for welding situations where the area to be welded can’t be easily cleaned or for site welding where wind conditions can make MIG and TIG welding impractical. Also used for welding the likes of cast iron.

- Silver Solder – commonly used for brass fittings, copper tube, etc and is also useful for joining dissimilar metals such as brass to stainless steel.